A tire factory might not sound like the most exciting place to visit, but when Nokian Tires invite you to see what is considered to be the world's most advanced tire manufacturing factory, it's hard to say no.

The Russian based factory, located just outside of St Petersburg, is the newest tire factory in Europe. It is highly automated, and currently produces over 45,000 tires every single day of the year with just over 1,000 staff. As reference, a competitors tire factory which produces less than 10% more tires, requires over four times the number of staff. The new factory is a showcase of Nokian Tires premium manufacturer credentials, and impressive investment in technology.

Inside

The tire factory is wonderfully clean considering it mixes, cooks, presses, burns, weaves and cuts very messy ingredients such as natural rubber, carbon black and silica.

The automation is even more impressive. Swarms of laser guided self driving forklifts hum around the factory, moving the fifty trucks worth of raw materials that arrive each day first to storage, then to the mixers, then the mixed compound to the construction area. Once green tires are produced, huge robotic arms move them from the construction machines, to belts, to ovens. Some of these incredibly complicated machines were co developed with Nokian tires, giving them two years exclusivity on the technology.

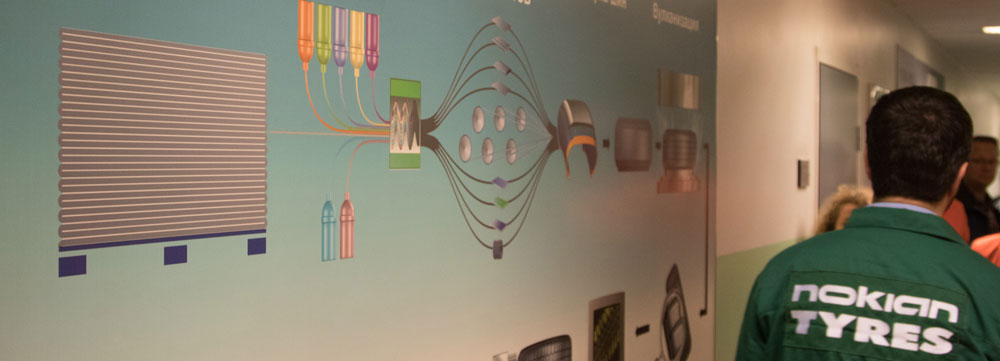

The Process

Making a tire is incredibly complex. Not only are you mixing carefully measured quantities of up to one hundred ingredients into the compounds used, the first and last steps of the process requiring careful control of mixing, temperature and pressures to ensure the perfect chemical reactions happen to create the best possible tire.

The rubber, carbon black, silica and other components are mixed under high heat and pressure into the base compound, which is then rolled into sheets.

The strong apex bead and sidewall sections are constructed with steel cording. This gives the tire the ability to sit firmly on the rim, and is a key part of the tires structure.

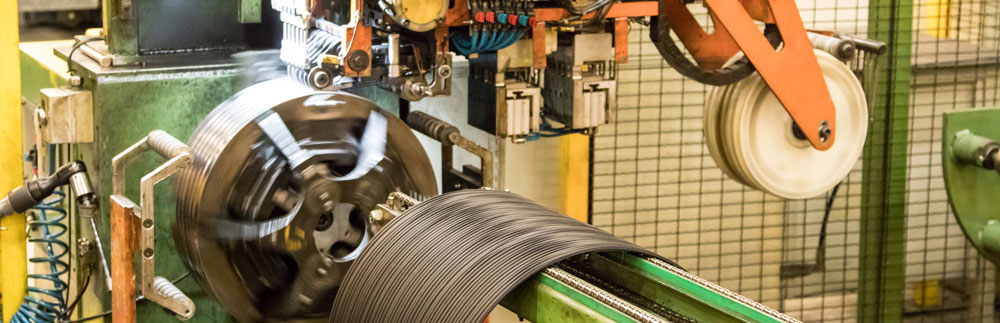

The main structure of the tire tread is laid with two layers of steel cords, cut to length, and pressed back together at opposing angles for increased strength.

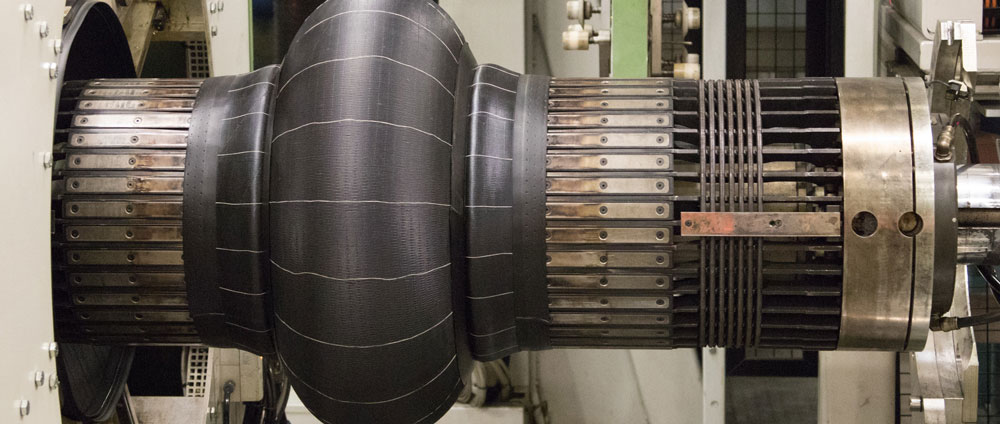

An air tight inner tube is created from a butyl rubber compound on extrusion lines. Tread and sidewall are made with extrusion and comprise of 3-5 different compounds. All the elements are assembled together. The innertube first has the sidewalls, body ply and the apex bead applied. This is then joined together with a bracelet of nylon jointless belt winded on two layers of steel belt, and the tread is laid over the top to make the final, "green" tire.

The green tire goes off to be cured where it sits in a high pressure hot oven for around 12 minutes. This gives the tire its tread pattern and vulcanises the rubber, which changes it from a relatively weak compound to something that can take the daily abuse we face on the roads.

Tire is then moved for manual inspection. The manual inspection is one of Nokian Tires key stages in order to make sure only perfect tires leave the factory, and is a highly skilled job. Tire inspectors will have worked at the factory for at least a year in other roles before being considered.

The manually approved tires goes through a second automatic inspection for final checks. If passes it gets labeled and moved to the warehouse.

During this process, samples of both the compound and fully constructed tires are automatically taken and sent to the on site labs for quality testing. This ensures each Nokian tire produced meets the premium quality of the Nokian Tires brand.

The factory is like a mini town in itself. It has a bank, a dedicated Doctor, a gymnasium with free personal training sessions on offer, and an excellent canteen. The canteen, which is subsidized for the employees, is a central place where everyone in the company meets and eats, from the CEO to the floor workers, which strengthens the community feeling.

With this level of investment and technology, it's easy to see why Nokian Tires are considering a premium tire manufacturer in Europe.